The packaging industry combats plastic waste by adopting sustainable design, reducing material use, promoting reuse and recycling through mono-material packaging, and embracing biodegradable alternatives. These strategies build a circular economy that keeps materials in use, reducing environmental impact and plastic pollution.

You know the drill – it’s everywhere, isn’t it? Splashed across the news, clogging up your social feeds, and even turning up on those pristine beaches we all dream about. Plastic waste? Yeah, it’s basically the villain of our modern era. If you’re running a business these days, the heat from customers and lawmakers is cranked up to eleven. The real question isn’t whether to go green with your packaging anymore – it’s how to do it without breaking a sweat, and how quickly you can pull it off.

But what’s really bubbling away behind the curtain to flip this mess around? I’ve been knee-deep in the paper packaging game for over a decade now, and let me tell you, I’ve got the best seat in the house for this wild ride. It’s chaotic, sure, and full of headaches, but man, the ingenuity and sheer determination out there? It’s inspiring. In this piece, I’m diving straight into the nitty-gritty questions that packaging folks and brand bosses fire at me all the time – no fluff, just the good stuff.

How on Earth Did Packaging Turn into Such a Plastic Nightmare?

For what feels like forever – well, most of the last century, anyway – our whole economy chugged along like a one-way train: grab resources, whip up products, and chuck the leftovers in the bin. This “take-make-toss” routine handed us cheap, handy packaging on a silver platter, but it also dumped a mountain of rubbish on our doorstep. Plastic, with its superhero-level flexibility and toughness, became the ultimate symbol of this throwaway life.

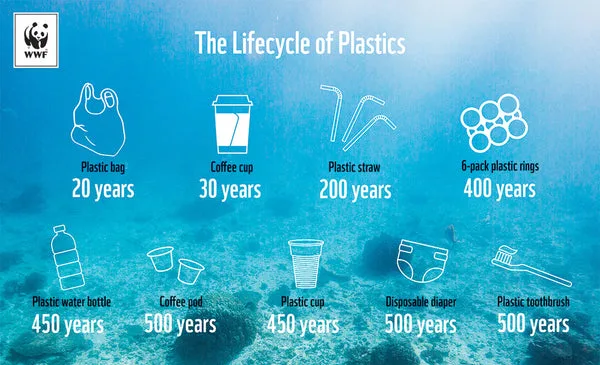

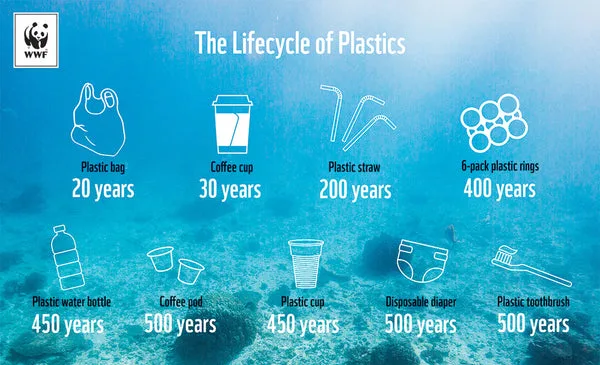

The kicker? Most of that plastic was built for a quick fling – straight to the dump, no second dates. Those fancy multi-layer films, dodgy dyes, and glues that stick like superglue? They turn recycling into a total farce, if it’s even possible at all. It’s enough to make you want to pull your hair out. Thankfully, the industry’s waking up and steering us off that dead-end path towards something smarter: a circular economy, where we keep materials dancing in the loop for as long as we possibly can.

The Down-and-Dirty Strategies: What’s Really Shaking Things Up?

Going sustainable isn’t about waving a magic wand – it’s a gritty, all-hands-on-deck fight, powered by the old-school basics of reduce, reuse, and recycle, but jazzed up with some seriously cool tech. Let’s unpack the moves that are actually moving the needle in the packaging world.

Picture this: the simplest trick in the book is just using less stuff right from the start. Sounds basic, right? But it’s genius when you rethink your designs with a bit of clever engineering. Take “lightweighting” – engineers are slimming down bottles so they guzzle way less plastic, yet still hold up like champs. I’ve watched brands slash thousands of tons of waste annually by ditching those bulky handles on big jugs. Tiny tweak, massive win. Or swapping out extra layers – remember those cereal bar multipacks wrapped in film? Now they’re snug in a nifty, recyclable paperboard sleeve. It’s all about that “less is more” vibe, and trust me, a sharp packaging partner can spot savings in your supply chain you’d never dream of, making everything sleeker and sharper.

Then there’s reuse – oh, what a powerhouse against our one-and-done addiction. It’s got its fair share of logistical knots to untangle, but refill systems are finally catching on. Big players are testing setups for stuff like cleaning sprays or shampoos: snag a sturdy bottle once, then top it up with simple pouches or at store stations. I once teamed up with a company that etched this subtle texture into the base of their reusable containers. Why? To camouflage the everyday dings and scratches, stretching the bottle’s lifespan from a measly few uses to over 25. It’s one of those little “aha” moments that really amps up the circular magic.

For the stuff that can’t loop back as is, the goal is making recycling a breeze. Enter “designing for recycling” – the phrase that’s become everyone’s mantra. Mono-material packaging is stealing the show here; forget those nightmare laminates that are impossible to separate (like trying to unmix a baked cake). Instead, we’re seeing pouches and films made from just one plastic type, like polyethylene, which sorts and recycles like a dream.

Even the fiddly bits count. Ever wrestled a sticky label off a bottle? That residue can wreck an entire recycling batch. Cue the heroes: wash-off labels and adhesives that peel away cleanly in the plant’s wash cycle, leaving behind pure, top-notch plastic ready for round two.

And hey, are there solid swaps for plastic altogether? Absolutely! The hunt for eco-friendly alternatives is firing up innovations that blow my mind, way beyond just fiddling with plastic.

Recycled content is huge – think Post-Consumer Recycled (PCR) or Post-Industrial Recycled (PIR) materials that slash our reliance on fresh, oil-guzzling plastics. It’s not perfect; nailing a steady supply of food-safe recycled stuff is a real puzzle, but purification tech is smoothing it out year by year.

Biodegradable options are buzzing too, but let’s get the terms straight – “compostable” is the real deal, breaking down into nutrient-rich soil in proper facilities. Ideal for coffee cups or food trays, but only if the collection game’s on point.

And don’t get me started on paper-based goodies – that’s my jam at C MIC Packaging. We’re talking tough corrugated boxes that shield shipments, or swanky rigid boxes for that premium unpack feel. Paper’s renewable, breaks down naturally, and recycles like a pro. Plus, fresh barrier coatings are letting it step in for flexible plastics in snacks or coffee packs. Who knew cardboard could be such a rockstar?

Pulling It All Together: Crafting a Proper Circular Economy

All these bits – trimming down, looping back, recycling smarter, and dreaming up new materials – they’re the puzzle pieces for a true circular economy. Swap the dead-end road for a lively roundabout, where nothing hits the landfill wall; it just keeps whizzing around, creating fresh value.

But here’s the rub: no one’s building this solo. It takes wild teamwork. Take Tetra Pak and Lactalis – they’re turning old cartons into certified recycled polymers for new ones, nailing a closed-loop system that scales beautifully. Or SIG’s gig in Egypt, bootstrapping a whole recycling chain from scratch, transforming local trash into treasure.

Picking a Packaging Partner Who’s the Real Deal on Sustainability

Wading through sustainable packaging options? It can feel like a maze. The best partners aren’t just flogging boxes; they’re your sherpa through the chaos. Look for ones who dive deep into your designs, tweaking every crease to slash waste while keeping your product safe and shelf-ready. Their toolkit should be packed – FSC-certified paperboard, high-PCR plastics, the works – so you get what’s right for you, not just their bestseller.

They’ve got to fuss over the details too; going green shouldn’t skimp on quality. Expect obsessive testing to make sure your package nails it from factory floor to front door. And ultimately, they should feel like true collaborators, getting your brand’s quirks, budget woes, and ops headaches to whip up something custom that clicks.

The Road to a Cleaner Tomorrow Starts Today

The packaging biz is at a real turning point – tough, yeah, but the buzz of innovation? It’s electric. By getting savvy with designs, hugging new materials, and teaming up big time, we’re flipping a planetary headache into a golden chance. Packaging’s not just about wrapping a product anymore; it’s about wrapping our arms around the planet.

Fancy making your packaging a force for good? Drop us a line at C MIC Packaging – let’s chat and map out your path.