Introduction: The Unsung Hero of Product Packaging

Imagine the frustration: after endless hours refining your product, the packaging arrives, and it’s a complete disaster. It’s a heart-sinking experience that haunts many entrepreneurs. Whether the box is the wrong size or the design misses the mark, such blunders can drain your finances and tarnish your brand’s image.

This is where a packaging sample emerges as a true guardian. Before you commit to mass production, securing a sample can be the pivotal step between a seamless launch and a budget-breaking fiasco. Let’s delve into why the importance of packaging samples is a non-negotiable priority—it’s your shield against wasted time, squandered funds, and damaged credibility.

Consider the broader landscape: the sustainable packaging market is soaring, expected to grow from $292.71 billion in 2024 to a staggering $423.56 billion by 2029, with a robust growth rate of 7.67% annually. This surge, driven by consumer demand for eco-friendly solutions, highlights the urgent need for precision in packaging choices. Samples allow you to test and refine, ensuring your design aligns with these green expectations before it’s too late.

Moreover, regulatory pressures are tightening globally. From Thailand’s ban on single-use plastic bags to stringent recycling laws in France, Germany, and the UK, compliance is no longer optional. Packaging samples act as a safety net, helping you verify adherence to these rules and dodge hefty fines or reputational harm. After all, a small upfront effort can prevent a monumental setback.

Then there’s the wave of innovation reshaping the industry. Think smart packaging with RFID tags, edible materials, or tailored portion-controlled designs—exciting, yet risky without proper testing. Sampling lets you experiment with these cutting-edge ideas, ensuring they function as intended and match your vision before full-scale rollout.

Additionally, consumer trends are shifting fast. With e-commerce booming and on-the-go lifestyles rising, the single-use packaging market is projected to hit $50.34 billion by 2029, fuelled by demands for convenience and safety. Packaging samples bridge this gap, allowing you to balance functionality with sustainability, meeting customer needs without costly missteps.

Finally, the economic stakes are high. The custom packaging market, valued at $43.88 billion in 2023, reflects a growing appetite for bespoke solutions. By investing in samples, you safeguard against errors that could erode your budget or brand trust. In essence, a sample isn’t just a preview—it’s a strategic tool to navigate a complex, evolving industry with confidence.

Why Should Packaging Samples Be on Your Radar?

Imagine the sting of launching a product, only to face a wave of customer feedback about flimsy or ill-fitting packaging. This is a pitfall I’ve witnessed repeatedly when businesses bypass the vital sample approval stage. A sample isn’t merely a sneak peek; it’s your opportunity to refine flaws before they snowball into costly blunders. In sectors like e-commerce or retail, where unboxing shapes much of the customer’s impression, a sample serves as a crucial rehearsal—spotting issues before the spotlight hits.

Yet, the value of samples extends beyond error prevention. They address pressing concerns: Can this packaging endure a bumpy journey? Does it instantly reflect “my brand” to the onlooker? These aren’t mere practicalities; they’re powerful signals of reliability to both customers and partners.

Moreover, samples enable rigorous testing of material durability—ensuring the packaging holds strong during transit or storage. Holding a tangible prototype in your grasp instils the assurance to declare, “This isn’t just a container—it’s the first impression my brand makes.”

Beyond this, packaging samples foster seamless teamwork across departments like design, marketing, and quality control. They provide a unified platform for all stakeholders to evaluate and approve, minimising miscommunication and guaranteeing that the final design meets every standard. Additionally, samples open the door to early consumer feedback, pinpointing design missteps and ensuring the packaging resonates with your brand’s identity. This step is invaluable in making it stand out on crowded shelves.

What’s more, investing in samples upfront can save significant costs down the line by catching potential flaws before mass production. It prevents expensive reprints or recalls due to substandard or non-compliant designs, while a clear timeline for sample delivery ensures smooth integration into production schedules. Above all, consistent, high-quality packaging—validated through samples—nurtures brand reputation and fosters customer loyalty. When your packaging mirrors your brand’s promise, it doesn’t just protect the product; it elevates trust and drives lasting connections.

What Problems Can a Packaging Sample Fix?

Let’s get real about the headaches a prototype packaging can prevent. Over my years in the industry, I’ve witnessed these pain points firsthand—and samples are often the cure.

Nailing the Perfect Fit

Have you ever opened a package to discover the product rattling inside—or, worse, crushed by a snug fit? It’s a quiet betrayal that erodes customer confidence. A structural sample offers a chance to perfect the dimensions, ensuring your product nestles in as snugly as a hand in a glove. Consider an item with an unusual shape; without a prototype, you risk overlooking minor tweaks crucial for safeguarding it during transit. Testing a sample lets you spot these hiccups early, long before you’re saddled with a stockpile of ill-fitting boxes.

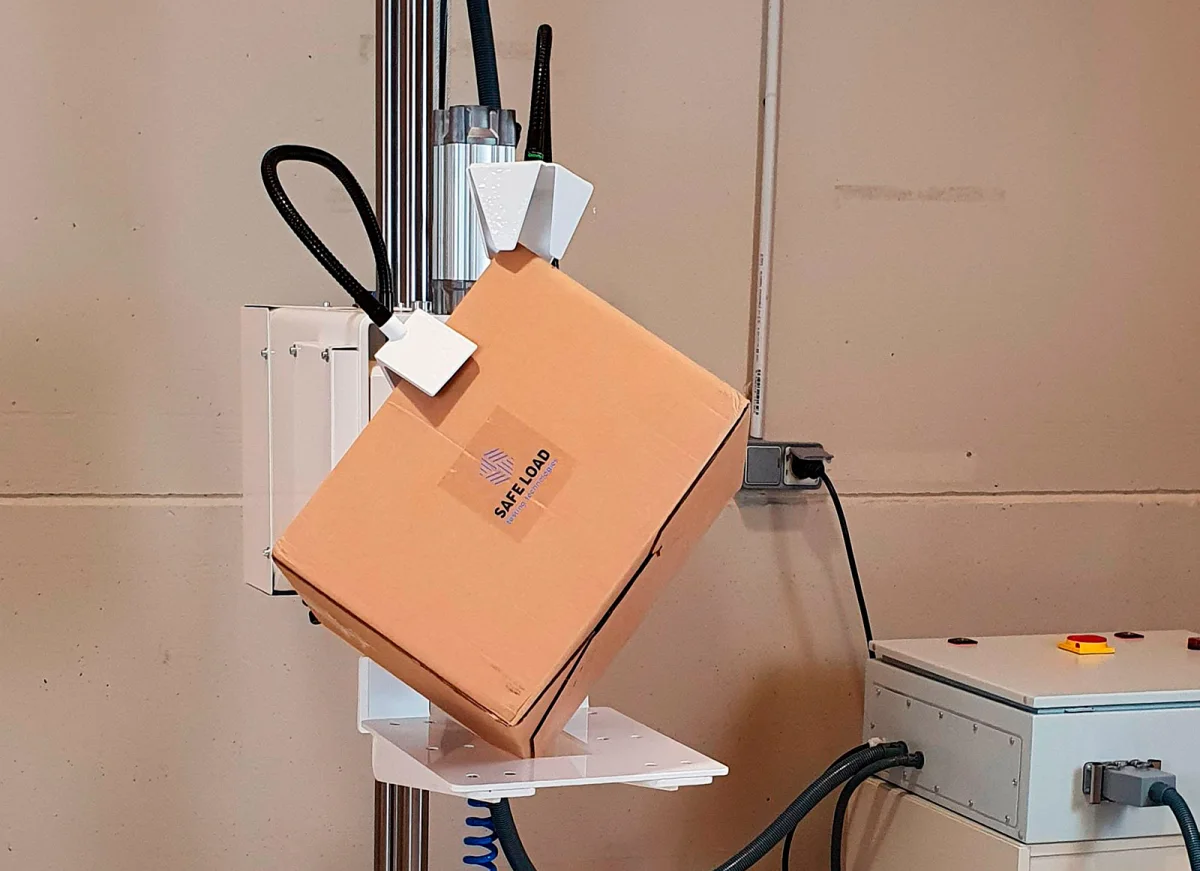

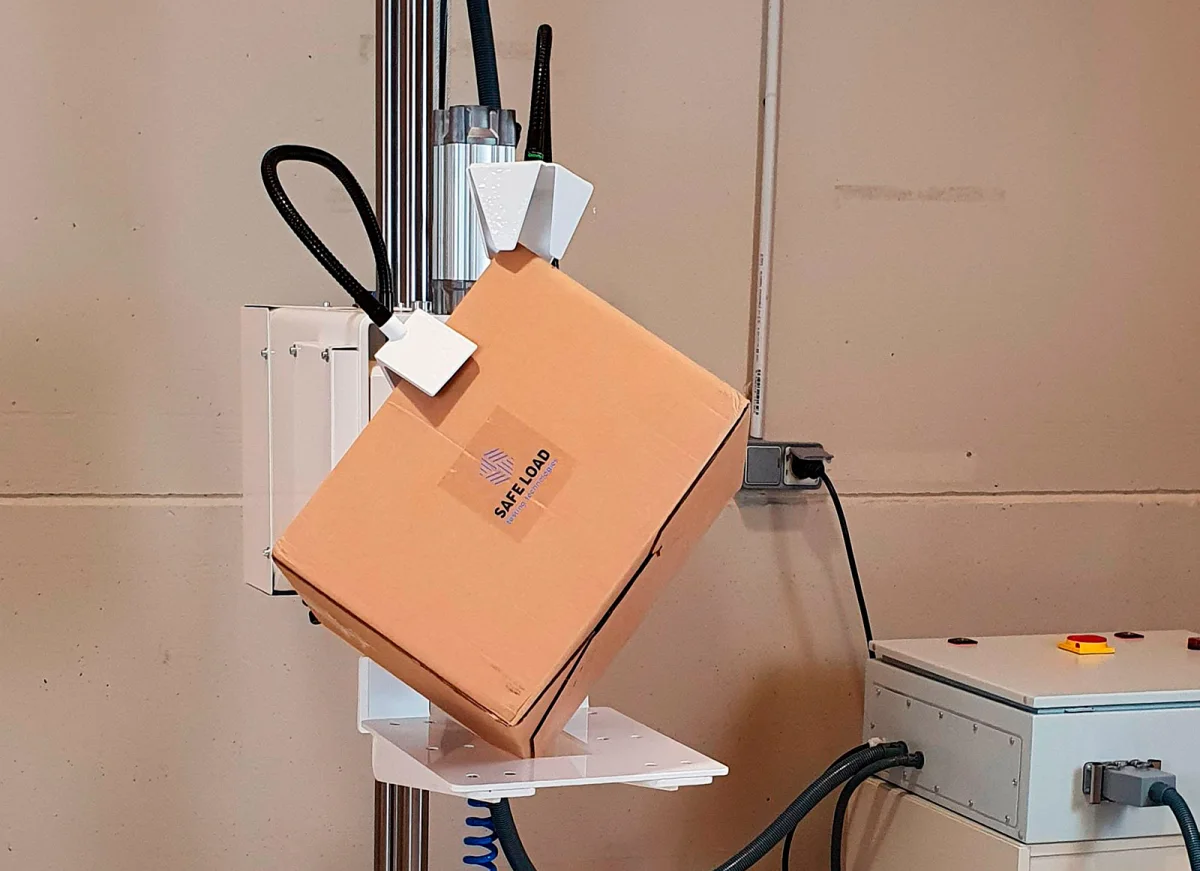

Beyond mere fit, samples enable critical performance testing, mimicking real-world conditions like vibrations, compression, and drops. For instance, a drop test can confirm whether the packaging shields the product’s integrity from various heights and angles. This is especially vital for quirky or complex shapes, such as delicate electronics or precision tools, which often demand bespoke packaging. Through sample testing, you can fine-tune the design to prevent damage, ensuring safe delivery every time.

Moreover, packaging samples streamline supply chain logistics. By experimenting with dimensions and materials, you can determine if extra protection is needed and optimise stacking or storage during transport. This not only slashes shipping costs but also boosts efficiency and minimises the risk of loss. Thus, a simple prototype becomes a powerful tool for cost-saving innovation.

In the design phase, samples serve as a tangible way to validate ideas against real-world needs. Using technologies like 3D printing, you can swiftly create and tweak prototypes, ironing out potential flaws before production. This hands-on approach ensures every detail aligns with expectations, transforming a concept into a reliable solution with ease.

Finally, collaborating with manufacturers becomes smoother with a physical sample in hand. It acts as a bridge, conveying precise requirements and ensuring the final packaging meets high standards. Such teamwork reduces errors, enhances production efficiency, and guarantees quality. Ultimately, a well-tested sample paves the way for trust—both in the product and the process.

Perfecting Design and Visual Impact

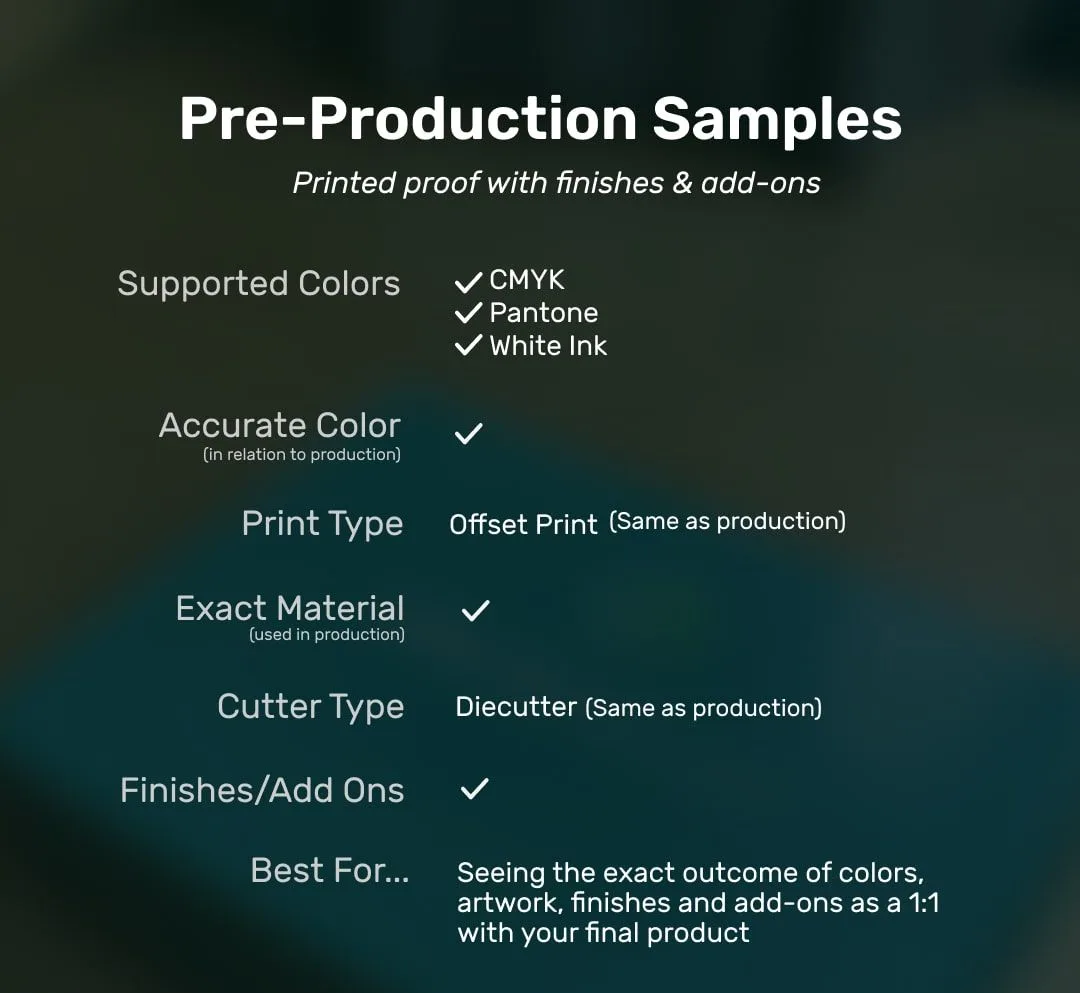

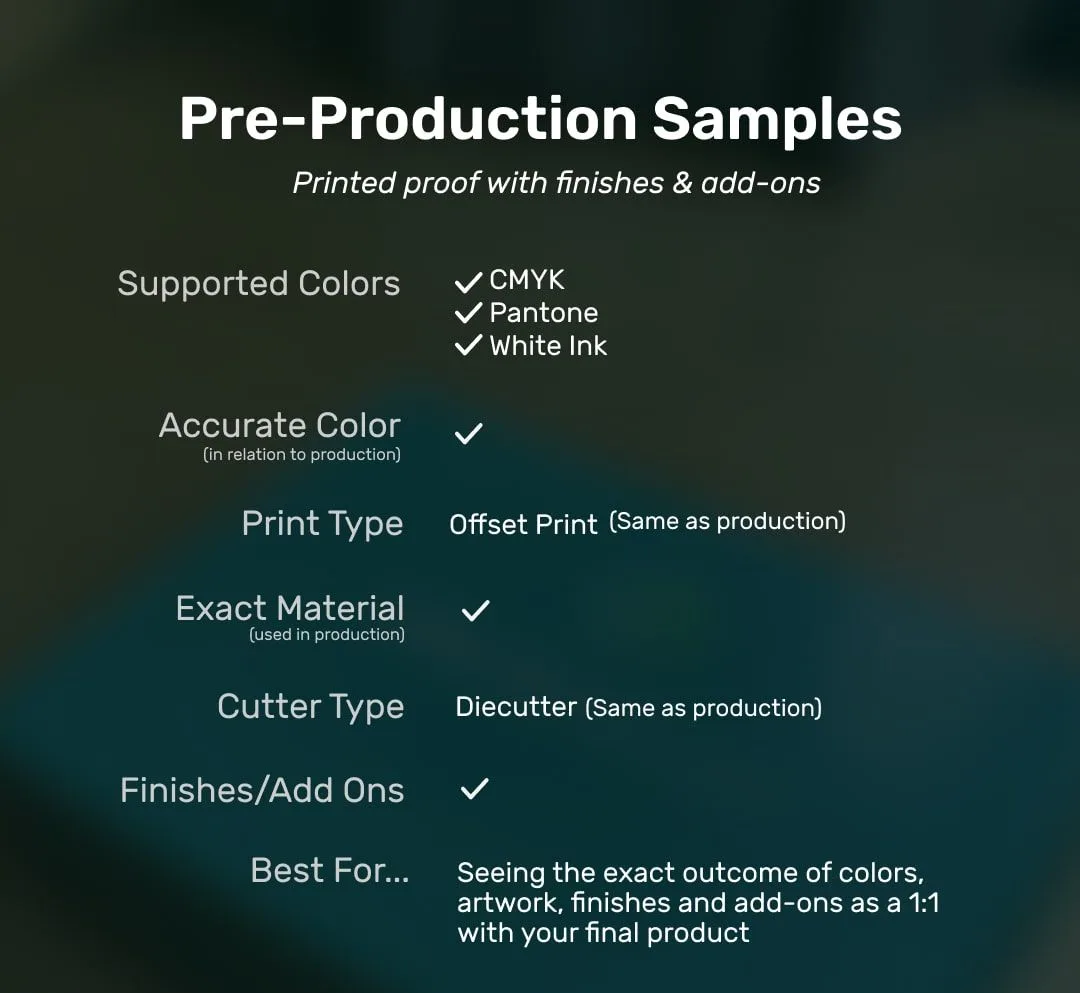

Your design may dazzle on a digital screen, yet the transition to print can be a tricky beast. Colors might lose their vibrancy, or intricate details could blur into obscurity. Through a packaging design evaluation, a pre-production sample reveals the authentic appearance of your print, branding, and finishes. I recall a project where a client’s logo shone brightly online but appeared lacklustre in hand—thankfully, a sample allowed us to refine the hues for a striking, unforgettable impact.

Beyond mere colour, samples are vital for ensuring consistency in materials. What looks flawless digitally often shifts when touched by reality, as lighting or texture can alter perception. Testing a sample lets designers see how shades and surfaces harmonise with the environment where the product will ultimately sit, preventing surprises like muted tones under store lights.

The tactile allure of packaging, shaped by finish and texture, also demands attention. Whether it’s a matte elegance, a glossy sheen, or a rugged feel, samples help confirm that these choices resonate with the brand’s essence and customer expectations. After all, the way packaging feels in hand subtly sways how consumers judge a product’s worth.

Moreover, branding and logo integrity hinge on these early checks. A sample ensures that logos and key elements print sharply and uniformly across every unit, safeguarding brand identity. Without this step, even a slight misalignment could tarnish a professional image, making thorough testing indispensable.

Environmental factors, too, play a sneaky role in design outcomes. Light, humidity, or temperature can warp appearances or degrade materials over time. By exposing samples to varied conditions, designers can spot potential flaws—be it fading on a sunlit shelf or warping in damp climates—and tweak accordingly.

Finally, for packaging meant to shield during transit, samples test endurance under minimal and maximal loads. This ensures the design stays intact and appealing, even after rough handling. Consequently, such rigour preserves both the product’s safety and the packaging’s visual charm throughout its journey.

In essence, these steps, from colour fidelity to stress testing, weave together to guarantee that the final packaging not only captivates the eye but also endures real-world challenges. Thus, samples stand as the unsung heroes, bridging the gap between vision and reality with unyielding precision.

Stress-Testing Durability

Let’s be honest: shipping is a rough journey. Can your packaging endure accidental drops, fluctuating humidity, or the weight of heavier boxes stacked on top? Through product packaging testing, a sample becomes your testing ground to replicate real-world turmoil. Be it corrugated or rigid boxes, this rigorous evaluation ensures your design stands firm against all odds. Imagine it as a gruelling training regime for your packaging—only the strongest survive to face the shipping frontier.

Beyond basic durability, compression and stacking tests are vital to confirm your packaging can bear the burden of heavy loads, especially during palletised or containerised transport. Following standards like ASTM D642, these tests measure the maximum weight a package can handle without buckling, safeguarding your goods in towering stacks. Similarly, climate conditioning tests expose samples to extreme temperatures and moisture levels, mimicking the harsh conditions of storage and transit. This is crucial for sensitive items like food or pharmaceuticals, where seals and adhesives must hold to prevent spoilage.

Moreover, drop testing, guided by standards such as ISO 2248, simulates the inevitable bumps and falls during handling, ensuring your packaging shields its contents from vertical shocks. This proves invaluable for delicate electronics or industrial tools, where even a single impact can spell disaster. Likewise, vibration and shock tests replicate the relentless jolts of road, air, or sea travel, verifying that your design can endure the journey unscathed. For shipments exposed to the elements, water resistance testing becomes a lifeline, protecting contents from rain or dampness in challenging climates. For tips on protecting fragile items, explore how to safely ship fragile products.

Importantly, adhering to globally recognised benchmarks like ASTM and ISO—such as ASTM D5276 for drop protocols—ensures your packaging meets stringent durability and safety standards. Therefore, by stress-testing samples under these varied conditions, you not only enhance product protection but also build trust with customers. Think of this process as crafting an impenetrable fortress around your goods, ready to weather any storm the shipping world throws its way.

Shaping How Customers See Your Brand

Packaging is far more than a mere container; it’s a powerful narrator of your brand’s story. A frail, uninspired box murmurs “mediocre,” while a sleek, robust design roars “exclusive.” By testing a sample with a small focus group, you can gauge consumer perception of packaging. Do they sense opulence or mediocrity in the touch? Their feedback becomes a compass, guiding your design to etch a memorable mark in their minds.

Beyond first impressions, packaging weaves an emotional thread with customers through storytelling. When it reflects your brand’s values or the product’s origins, it transforms a simple item into part of a cherished narrative. This connection, as studies suggest, fosters deeper engagement and loyalty, making your product resonate on a personal level.

The silent language of colours and typography in packaging speaks volumes to the psyche. Warm reds spark excitement and urgency, while calming greens hint at sustainability and wellness. Likewise, a font’s style can whisper elegance or shout innovation, shaping how your brand is perceived. Aligning these elements with your core message is vital to crafting the right image. Learn more about building a consistent brand identity through packaging.

Moreover, superior packaging builds a bridge of trust, elevating the perceived worth of your product. Research reveals that a striking 70% of buying choices unfold at the point of sale, where captivating designs can sway decisions. A well-crafted exterior suggests luxury, nudging consumers to believe the price mirrors the value.

Visual allure, too, plays a starring role in sparking impulse buys. Data shows that 76% of shoppers have snapped up items on a whim, swayed by eye-catching packaging. This underlines the need to design with boldness, ensuring your product grabs attention and boosts both sales and brand recognition.

Consistency in packaging across every customer touchpoint acts as a steady heartbeat for your brand. When design echoes through marketing and product alike, it carves a lasting identity in memory. Consequently, this unified approach polishes consumer perception, paving the way for trust and stronger sales.

Finally, in an era of eco-awareness, sustainable packaging emerges as a beacon of responsibility. Opting for green materials and minimalist designs can polish your brand’s reputation, appealing to earth-conscious buyers. Indeed, 67% of Americans admit that packaging materials often sway their choices, proving that eco-friendliness is not just a trend but a powerful influencer. Thus, with every design choice, packaging becomes a canvas to paint your brand’s essence. Dive deeper into what is eco-friendly packaging.

Dodging Expensive Blunders

Opting to bypass packaging samples may appear as a quick shortcut, but a single overlooked defect in a bulk order can spiral into a costly disaster. Emphasising error prevention in packaging through meticulous sampling ensures cost savings via early detection. Spotting a crooked logo or fragile material during the sampling phase spares you the burden of reprints or discarded stock down the line. Moreover, samples help curb material waste by pinpointing design flaws before mass production, potentially slashing waste by significant margins. It’s a modest upfront cost for a substantial long-term gain.

Beyond mere error correction, testing samples streamlines shipping and handling efficiencies. Fine-tuning the size and weight of packaging not only maximises space during transit but also trims shipping expenses and lowers the risk of damage en route. For instance, a slight tweak in dimensions, like adjusting a frozen pizza box, can yield considerable savings. Additionally, samples pave the way for a detailed cost analysis, allowing firms to weigh the return on investment across various designs and materials, striking a balance between quality and affordability.

Furthermore, collaboration with suppliers is bolstered through the use of samples, fostering standardisation and clarity. By sharing and approving sample designs, businesses ensure suppliers grasp exact specifications, minimising errors in the final output and nurturing stronger partnerships. Meanwhile, leveraging data from these samples fuels informed decision-making. Analytics can reveal trends in material costs or predict future savings, guiding companies to smarter choices before issues escalate. Explore 5 ways to improve your packaging process for more efficiency tips.

Lastly, packaging samples play a crucial role in regulatory compliance. Testing ensures adherence to standards like recyclability and material composition, helping dodge hefty fines and safeguarding brand reputation. In essence, what seems like a small step acts as a sturdy shield against financial pitfalls, weaving together efficiency, collaboration, and compliance with ease.

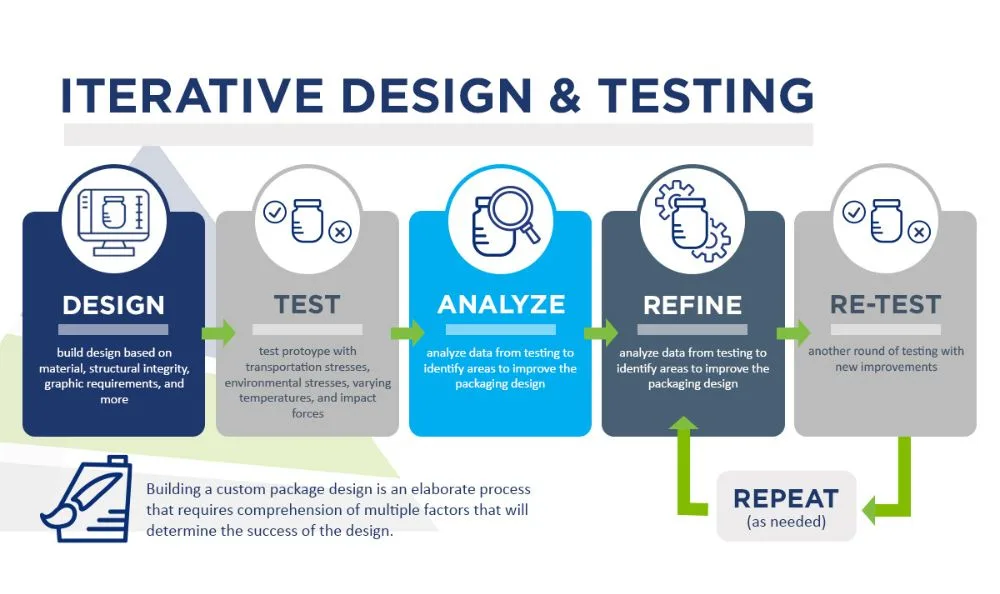

How Does the Sample Approval Process Unfold?

Ready to dive in? The sample approval process isn’t as daunting as it sounds. Here’s a straightforward path to guide you, ensuring quality assurance in packaging every step of the way.

Step 1: Pinpoint Your Priorities

Begin by identifying exactly what you’re testing—whether it’s dimensions, materials, aesthetics, or durability. Are you after a simple structural mock-up to check fit, or a detailed prototype with intricate details like embossing? Clearly outlining your objectives ensures your supplier delivers a sample that mirrors your vision. Be meticulous about specifying measurements, branding elements, and any distinctive features from the very beginning.

Next, consider the materials for your packaging. Testing various options, such as different papers, plastics, or eco-friendly composites, can reveal which best safeguards your product while aligning with sustainability goals. Conducting environmental tests—think humidity, temperature, or light exposure—helps assess how these materials hold up under real-world conditions.

Moreover, focus on functionality and user experience when defining your sample needs. Evaluate aspects like ease of opening, closing, or handling to ensure the packaging is user-friendly. For instance, child-resistant designs or easy-access options for seniors must strike a balance between safety and convenience, meeting the needs of specific audiences.

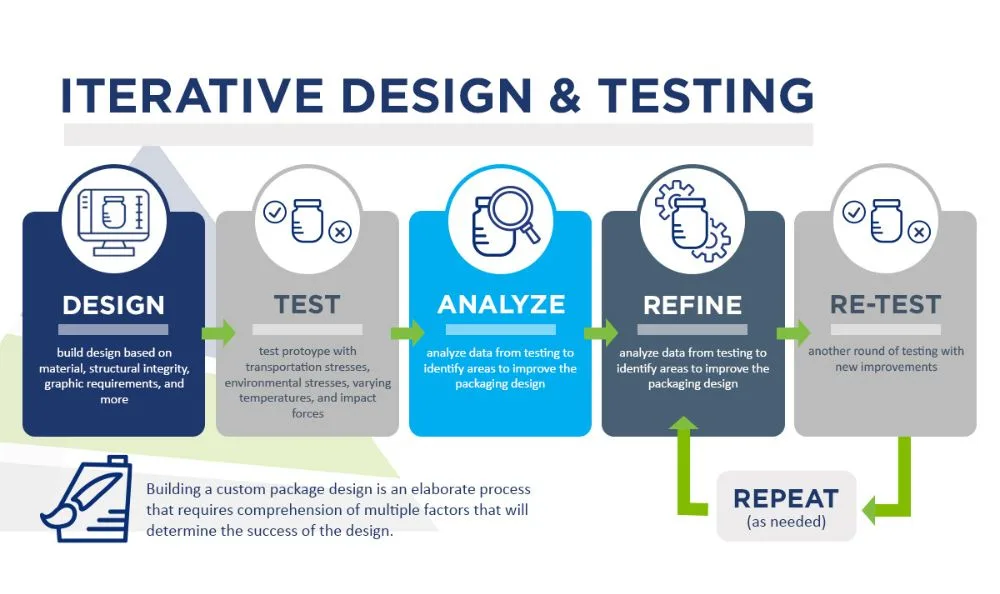

Additionally, embrace prototyping as an iterative journey. Testing multiple versions of your packaging design allows for continuous refinement, ensuring it meets both market demands and consumer expectations. This process not only polishes the look but also enhances practicality, ultimately boosting satisfaction and minimising returns.

Don’t overlook compliance with industry benchmarks. Ensure your samples are tested against recognised standards like those from ISTA or ASTM to confirm they can endure the challenges of transport and storage. Meeting these criteria isn’t just about toughness—it’s a safeguard against regulatory hiccups and legal risks.

Lastly, integrate a cost-benefit perspective into your sample testing. Comparing expenses across materials, designs, and production techniques can uncover cost-effective solutions without sacrificing quality. Meanwhile, sharing early designs with suppliers fosters supply chain collaboration, streamlining production and reducing errors from the outset.

Step 2: Build a Dialogue with Your Supplier

Open up a candid conversation with your packaging partner, laying out every detail of your vision. Transparent communication ensures that the sample mirrors your ideal design, leaving no room for guesswork. Feel free to ask for multiple options—perhaps a simple, unadorned box alongside a vibrant, branded one—to weigh your choices. Suppliers like C MIC Packaging excel in this arena, bringing a wealth of expertise to refine your concepts into bespoke packaging solutions. Their seasoned advice, often rooted in spotting potential pitfalls like material mismatches, can transform your ideas into reality.

Moreover, tapping into a supplier’s knowledge helps preempt design blunders before they spiral into costly errors. By co-creating physical samples, you can catch issues like misaligned prints or structural weaknesses early, saving time and resources. This collaborative approach also opens doors to cost-effective tweaks—testing varied materials or printing styles to strike the perfect balance between quality and budget. For instance, a supplier might recommend a sturdy yet affordable corrugated cardboard based on past projects. Check out 6 cool packaging ideas surprisingly inexpensive for budget-friendly inspiration.

Beyond functionality, this dialogue can elevate your brand’s identity through tailored design elements. Custom samples let you experiment with unique colours, logos, and even personal touches like handwritten notes, ensuring your packaging tells your story. Additionally, it’s a chance to enhance the unboxing experience—think ease of opening or a premium feel that captivates customers from the first touch.

Furthermore, suppliers often bring industry-specific insights, crafting solutions for niche needs, whether it’s meeting strict pharmaceutical standards or weaving sustainability into your design. Discussing eco-friendly materials or waste-reducing layouts not only aligns with environmental goals but also boosts your brand’s appeal to conscious consumers. Ultimately, this partnership turns a mere box into a powerful extension of your brand.

Step 3: Explore Different Sample Options

Samples come in various forms, each tailored to a unique purpose in the design journey. A plain sample prioritises the bare bones of structure, ensuring functionality without the distraction of visuals. Meanwhile, a digital sample offers a glimpse into the creative realm, showcasing artwork and design elements with speed and flexibility. Then there’s the pre-production sample, a near-perfect reflection of the final product, blending structure and style into a polished package. By experimenting with these diverse types, you safeguard your design from blind spots, refining every detail with precision.

Diving deeper, plain samples act as the foundation, allowing you to perfect structural integrity before aesthetic considerations take hold. Digital samples, on the other hand, shine in rapid prototyping, letting designers test multiple iterations swiftly without the hefty costs of physical mocks. This accelerates feedback loops and slashes time-to-market, sometimes by as much as 30%, as industry studies reveal. Consequently, adjustments become a breeze, ensuring the design evolves without draining resources.

Moreover, pre-production samples are a goldmine for collaboration, uniting teams like marketing and quality control for comprehensive feedback. Sharing these across departments helps catch discrepancies early, ironing out wrinkles before they become costly errors. Similarly, digital samples can engage a wider audience, including potential consumers, through surveys or focus groups. This early validation shapes designs that resonate, saving significant investment down the line.

Beyond functionality, samples are guardians of brand identity, ensuring logos, colours, and messaging align seamlessly across products. They also open doors to innovation, allowing tests of cutting-edge features like QR codes or smart packaging in a virtual space. Thus, through this layered approach, samples not only polish the design but also weave in value, blending efficiency with creativity. Each stage, from plain to pre-production, builds a bridge to a final product that stands out on the shelf.

Step 4: Put It to the Test

Once your packaging samples arrive, dive right in. Slide your product into the design—does it nestle in securely? Scrutinise the print—do the hues pop as expected? Test its durability by dropping the package—does it hold up under pressure? Beyond this, simulate real-world scenarios like stacking or harsh climates to uncover hidden flaws in stability or material resilience. Involve your team or loyal customers for candid insights. This thorough packaging design evaluation ensures no detail slips through the cracks.

Don’t stop at the basics; assess the user experience with care. Test how effortlessly the package opens or closes—could it frustrate a senior or pose risks to a child? Ergonomics matter, as a user-friendly design boosts satisfaction and curbs returns. Moreover, delve into sensory elements—does the texture feel premium, or does the opening sound cheap? These subtle cues shape how customers perceive your brand during that first unboxing moment.

Additionally, consider the journey your packaging endures. Evaluate its performance in varied orientations or as part of a unit load to ensure it remains steady during transit. Subject it to environmental simulations—think high humidity or freezing cold—to confirm it withstands diverse conditions without cracking or warping. Such rigorous testing, from tropical heat to arctic chills, safeguards your product’s integrity across global markets.

Finally, think long-term with lifecycle testing. Assess how your packaging fares from production to disposal—can it be recycled or reused? Aligning with sustainability goals not only meets regulations but also resonates with eco-conscious consumers. Furthermore, verify your suppliers’ credentials through audits, ensuring they meet quality and environmental standards. By weaving these layers of evaluation, as well as connecting durability with sustainability, your packaging becomes a trusted shield for your product.

Step 5: Refine and Revise

Noticed a flaw? This is your chance to make adjustments. Perhaps the material feels flimsy, or the branding seems off-kilter. Share your feedback with your supplier to request a revised sample if needed. This iterative dialogue is akin to chiselling a fine sculpture—each tweak hones the design closer to flawlessness.

When refining, pay attention to the tactile experience of the packaging. The texture of materials can shape consumer perceptions, with rough finishes often evoking a sense of natural authenticity and sleek surfaces hinting at luxury. Discuss these nuances with your supplier to ensure the feel aligns with your brand’s identity.

Leverage cutting-edge tools like 3D printing to speed up prototyping. This technology enables rapid creation of intricate shapes, allowing you to test and tweak designs without delays. Consequently, you can iterate swiftly, ensuring the packaging evolves with precision and efficiency.

Focus on structural balance, especially if pursuing lightweight materials for sustainability. Samples are vital to confirm that these lighter options still safeguard your product during transport. Thus, use this stage to verify both environmental goals and durability are met seamlessly.

Colour consistency across materials is another critical checkpoint. Variations in substrates like paper or plastic can alter hues, risking brand cohesion. By examining samples, you can ensure the shades remain uniform, projecting a polished and unified image to consumers.

Lastly, consider accessibility and innovation in your revisions. Test samples for ease of use among diverse groups to meet accessibility standards, and explore integrating smart features like QR codes. This ensures your packaging not only looks appealing but also enhances functionality and inclusivity.

Step 6: Grant the Final Approval

Once you’re delighted with the prototype, it’s time to give the green light for full production. This finalized design, often termed the “golden sample,” acts as the benchmark for every future batch, ensuring unwavering consistency. With a trusted partner like C MIC Packaging, their dedication to quality assurance in packaging instills confidence as you approve, knowing each detail aligns with your vision.

This approval stage mirrors critical validation processes like the Production Part Approval Process (PPAP), where every specification is meticulously checked to meet design and quality standards. It’s not just a nod; it’s a commitment to excellence, built on rigorous testing and alignment with industry benchmarks, such as those from the International Safe Transit Association (ISTA). Therefore, your sign-off becomes a seal of trust in the product’s reliability.

Collaboration plays a pivotal role here, as clear communication with your supplier ensures the sample reflects your exact requirements, from material choices to functionality. Moreover, thorough documentation and certifications are essential, safeguarding compliance with industry regulations. A partner like C MIC Packaging facilitates this through continuous feedback, ensuring the packaging withstands supply chain challenges like transportation and storage.

Finally, approval isn’t the end but a foundation for ongoing refinement. Using this sample as a baseline, you can incorporate feedback from stakeholders to enhance the design over time. Consequently, with each batch, you’re not just maintaining quality but elevating it, keeping your packaging ahead of the curve.

Deeper Dive: The Risks of Skipping Sampling

Let’s tackle the glaring issue head-on: what happens when you bypass sampling to rush the process? Picture this—thousands of packages shipped for an online store, only to find they’re the wrong size. Returns pile up, social media erupts with scathing feedback, and your brand’s reputation plummets. Or imagine pitching to a powerhouse like Amazon, only to realise your packaging doesn’t meet their stringent guidelines. A simple sample could have flagged this mismatch early. These aren’t mere hypotheticals; they’re disasters I’ve witnessed unfold. Sampling isn’t just a step—it’s your shield against catastrophe.

Moreover, sidestepping sampling can lead to crippling product recalls. Flaws like poor sealing or misleading labels often surface too late, triggering financial losses and tarnishing trust, as noted by industry studies. Sampling acts as a preemptive strike, catching these errors before they spiral into crises. It also ensures compliance with e-commerce giants like Amazon, whose strict rules on box dimensions and materials can result in rejected shipments if ignored. Testing a sample safeguards against such penalties, securing your supply chain. For beginners, refer to this e-commerce packaging guide for foundational tips.

Beyond risk mitigation, sampling sparks innovation. Experimenting with prototype packaging can reveal opportunities to boost functionality or embrace eco-conscious materials. I’ve seen clients uncover sustainable alternatives during this phase, captivating environmentally aware buyers while aligning with their values. Partners like C MIC Packaging often suggest creative solutions, blending utility with striking design to make packaging that truly pops. For instance, industry leaders like L’Oréal rely on iterative prototyping to craft standout designs, proving how sampling fuels originality.

Furthermore, this process can shrink your carbon footprint. By refining designs through samples, businesses cut waste and lower environmental impact—studies suggest that trimming packaging weight by just 1% could slash thousands of tons of CO2 emissions yearly. Sampling also fortifies supply chain resilience, testing durability to prevent damage during transit, a factor stressed by logistics experts like UPS. Ultimately, it shapes consumer trust, as high-quality packaging, perfected through testing, often signals a premium product to buyers.

In short, sampling stands as a cornerstone of success. It not only averts disasters but also fosters creativity, sustainability, and reliability, ensuring your brand shines in a competitive market.

Conclusion: Play It Smart with a Packaging Sample

In the whirlwind of product launches, a packaging sample is your secret weapon. It perfects fit, elevates design, ensures durability, influences customer opinions, and shields you from pricey missteps. Following a clear sample approval process turns doubt into certainty.

Why risk your brand’s image on a gamble? Test before you produce. Curious to experience the difference a sample can make? Connect with C MIC Packaging for custom packaging solutions that blend precision with passion. Let’s reach out to create packaging that doesn’t just protect your product—it captures hearts.