The packaging world is like that reliable mate who always has your back during shopping trips or online deliveries, but let’s face it, it’s also sneakily contributing to our planet’s big environmental headache. Picture this: every humble cardboard box, bit of plastic wrap, or padded envelope has its own carbon story, kicking off from digging up raw materials and wrapping up in the rubbish bin.

Nowadays, businesses are under real pressure from strict rules and those eco-savvy customers who want lower emissions, clever designs, and options that don’t trash the Earth. Sure, trimming that carbon footprint sounds simple, but it’s riddled with pitfalls—yet for the daring innovators, it’s a treasure trove of ways to shine.

In this chatty rundown, I’ll unpack the key challenges and opportunities for slashing carbon emissions in the packaging game, giving procurement whizzes, packaging buyers, and brand bosses some down-to-earth tips to actually make an impact.

Packaging does a cracking job of protecting our goodies and making them look tempting on the shelves, but come on—it’s leaving quite the eco-mess behind. Traditional plastics are born from fossil fuels, paper-making chugs through energy like it’s going out of fashion, and those mixed-material mash-ups? They make recycling a total farce. I’ve come across stats that blame packaging for about 5% of global greenhouse gas emissions, and with online shopping booming, that figure’s only climbing.

It’s a proper pickle for companies: you can’t just bin packaging altogether, but pretending its footprint doesn’t exist? That’s not flying anymore—it’s essential for staying in the game.

The Eye-Watering Cost of Switching to Green

Diving into green packaging materials often feels like a punch to the bank account at first. Fancy stuff like plant-based plastics, compostable films, or those quirky mushroom-derived alternatives are innovative, but they cost a bomb compared to bog-standard plastic. From my chats with procurement types, it’s a nightmare balancing skinny budgets with grand green ambitions.

That said, there’s a bright side: invest in renewable packaging solutions today, and you’ll sidestep hefty fines down the line, snag devoted customers, and break into premium markets where folks gladly fork out extra for eco-cred. And get this— as more gets made, prices are tumbling. I’ve witnessed it firsthand with bio-plastics dropping over the last few years.

The Chaotic Puzzle of Recycling

Recycling packaging can feel like piecing together a jigsaw with half the bits missing—utterly exasperating. Those flexible pouches mixing plastics and aluminium? Total no-gos for recyclers. Even plastic-coated paper, meant to be tough, often ends up in the tip. The chasm between what designers conjure up and what real-world waste systems can cope with is turning good vibes into grim reality.

But here’s where it gets clever: brands opting for mono-material packaging or nifty fibre tweaks score double points—easier recycling and lighter loads that trim emissions during shipping. I’ve watched firms buddy up with waste experts to create closed-loop systems, scooping up old packaging, breaking it down, and remaking it anew. It’s not just clever; it’s like alchemy, turning rubbish into gold.

Wading Through the Regulatory Jungle

Packaging rules change quicker than the weather. From the EU’s Packaging and Packaging Waste Regulation (PPWR) to the US’s Extended Producer Responsibility (EPR) setups, the demands are ramping up and all over the shop. For outfits operating worldwide, it’s a right headache trying to align with this patchwork of standards.

Still, staying one step ahead can really polish your brand’s image. Those who push beyond the minimum show true backbone in packaging industry sustainability, earning kudos from customers and collaborators. From what I’ve seen, teaming up with clued-up suppliers—like C MIC Packaging, masters of global regs—irons out the kinks and keeps you compliant no matter where you are.

Juggling Product Safety with Eco Smarts

At its heart, packaging is all about keeping things safe and sound, isn’t it? So, when you’re tweaking for sustainability, it’s a delicate dance: skimp too much, and you end up with damaged wares (and the extra emissions from replacements), but overdo it, and you’re churning out needless carbon. This is especially tricky in food or pharma, where extending shelf life cuts down on spoilage and waste.

The fun bit? Innovations like lightweight packaging technology and digital printing let you work smarter, not bulkier. Tailored fits mean less material waste and slimmer shipments, slashing emissions without skimping on quality. I’ve been involved in gigs where this switch alone saved firms a fortune in transport—it’s one of those wins that seems almost suspiciously perfect.

Harnessing the Magic of Recycled Stuff

One of the simplest carbon reduction strategies out there? Crank up the recycled content. Swapping in recycled plastics or paper slashes energy needs dramatically—recycled PET, for example, uses up to 79% less energy than the virgin kind, and recycled paper saves trees, turning down the dial on deforestation emissions.

It’s more than just carbon cuts; it kickstarts a circular economy where firms recycle loads and waste zilch, birthing new industries around recovery. In my experience, brands that dive in here create a domino effect, nudging suppliers and shoppers to get on board.

Diving into Nature’s Clever Alternatives

The boom in eco-friendly packaging innovations is downright exciting—it’s given us renewable wonders like:

- Mushroom mycelium boards that send styrofoam packing.

- Bagasse from sugarcane fibres for robust food trays.

- Cornstarch-based films that vanish into compost like a charm.

- Fibre-based trays ditching plastic moulds.

These break free from fossil fuels and decompose gracefully, setting the stage for deep, lasting carbon reductions. I’ve been amazed at how fast they’re growing—bagasse, for instance, has turned farm waste into a packaging powerhouse in under a decade.

Slimming Down the Supply Chain for Fewer Emissions

Sustainability in packaging isn’t just about the box itself—logistics are a massive emitter in the whole carbon emission challenges saga.

- Lightweight packaging eases the burden on lorries and planes.

- Right-size packaging maximises space, no air pockets.

- Regional sourcing cuts those epic global journeys.

Brands revamping their supply chain redesign often stumble on unexpected efficiencies alongside emission drops. I tracked one mid-sized retailer that shaved 15% off their carbon just by going local—proof that little changes pack a punch.

Going Digital to Make Production Greener

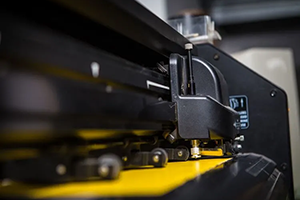

Digital wizardry is shaking up packaging with waste-busting bonuses. Digital printing ditches clunky plates, nails small runs, and supports just-in-time production to dodge overstock. Automation hones material use, trimming scraps and errors.

Together, they’re driving us towards low-carbon production standards. It’s thrilling how this levels the playing field—even tiny brands can now play the sustainability game without emptying their pockets.

Rallying Consumers to Join the Fight

Consumers aren’t mere bystanders; they’re vital in the packaging waste management cycle. All too often, bungled sorting sends recyclables to landfill. Brands that add clear labels—like “100% recyclable” or “compostable”—and spice it up with engaging education campaigns can nudge habits and nip emissions in the bud.

Return-and-refill programmes are sprouting up too, with perks tempting people to reuse. I’ve seen this build fierce loyalty—folks adore being heroes rather than culprits.

The Circular Economy: Packaging’s Bold Future

Peering into the crystal ball, the circular economy model is poised to rewrite the rules, viewing packaging as an endless loop: design, use, collect, recycle or compost, and round we go. It calls for bold thinking, helpful policies, and seamless supply chains, but the rewards? Massive! It transforms packaging from disposable junk to a renewable gem.

At C MIC Packaging, we’re fully committed—dishing out rigid boxes from recycled board, streamlined corrugated cartons, and FSC-certified paper that let businesses go green without cutting corners on quality. It’s the sort of forward-thinking that gets me buzzing about where this industry’s heading.

Wrapping It Up: From Hurdles to High Fives

Tackling carbon emission reduction in the packaging industry is a bumpy ride, packed with hefty costs, recycling riddles, and rules that shift like sand. But you know what? These headaches are the spark for brilliant ideas, solid partnerships, and revolutionary renewable packaging solutions.

The trailblazers who dive in—blending carbon reduction strategies, choosing green packaging materials, and roping in consumers—aren’t just scraping by; they’re smashing it and shaping a brighter world. Packaging doesn’t have to be the bad guy; it can be the star. The real winners? Those brave souls leading the way, showing you can safeguard products and the planet in one smart move.